How To Tell What Size Lift Leaf Springs I Have?

How to Properly Measure out Leaf Spring Size for Your Vehicle

On roads and highways across the United states, diverse types of vehicles deport heavy loads that often exceed the weight capacities of the cars, vans and trucks in question. Therefore, vehicles need all the gravity absorption they can muster.

In many types of vehicles and particularly in today's larger ones, leafage springs are used to provide gravity absorption and prevent suspension sag. This is peculiarly vital in pickup trucks, where rear axles can often become weighed down with heavy items — such as furniture and moving boxes, for case.

Forth the back terminate of a truck, van or SUV, leaf springs proceed the tires circular and the torso evenly horizontal along all terrain. Sooner or afterwards, however, the leaf springs that came with your vehicle will wear out. Equally you set nearly looking for replacements, it's best to know how to measure leaf spring length then y'all can better identify the needs of your vehicle.

Observe a Leafage Spring for My Vehicle

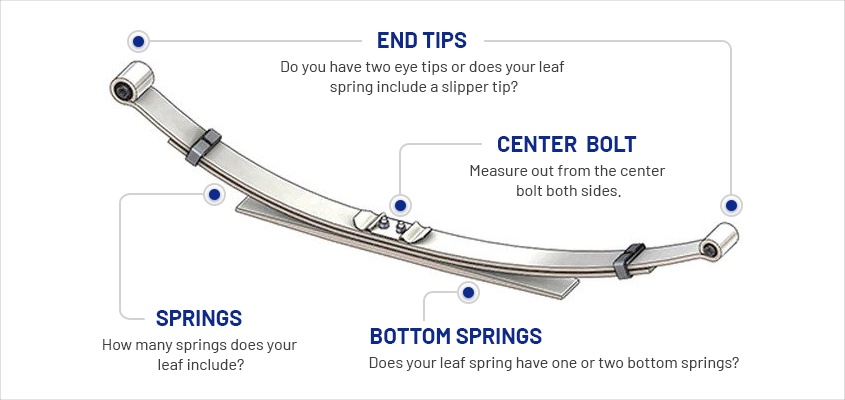

Parts of a Leafage Spring

If you're looking to replace your leaf springs for the first fourth dimension, it might be tough to determine exactly what size you lot demand. The first pace is checking what applications you demand – the best place to get is General Spring to run across if your application is one size fits all or if your application has multiple measurements. All the same, the easiest way to observe out the right size of leaf spring is to measure the springs that are currently on your vehicle. Earlier y'all tin can measure out, though, you lot'll demand to sympathise the shape and structure of leaf springs. The following parts are what you lot must know about leafage springs to make an accurate size determination:

- The springs

The springs are the long metal strips that serve as the operative pieces of the whole component. The springs are stacked in an inverted pyramid with the longest on pinnacle. Collectively, the springs form an inverted arch that is held in place by a center bolt. Additionally, the springs are bound together at the quarter-lengths with clips. On some pinnacle springs, the ends coil upwardly to form enclosed circles, which are referred to every bit "eyes." Most foliage springs consist of three, four or five leaf springs, but they can go even higher than that depending on the capacity needed. In short, springs consist of the following pieces and characteristics:- Metal strips (usually three, four or v)

- Inverted pyramid stack

- Inverted curvation shape

Additionally, you'll need to check your applications considering some leaf springs don't take multiple measurements, and it's one size fits all. Be certain to check on General Jump for your right application.

- The bottom spring

Below the stacked set of arched springs is a horizontal strip known as the bottom spring, which is a shorter, thicker flat leaf that serves as a rebound bound for the other springs. The bottom spring is known as the overload jump, merely since information technology doesn't add to the gravity assimilation, it could be more accurately thought of as a rebound spring. On most leaf springs, there'southward only one lesser spring, though some models consist of two. - The eye commodities

At or near the center of the top spring is a vertical bolt that holds everything together. While the bolt is usually located directly at the centre, some top springs volition measure out longer on one side than the other. The bolt connects all the springs in the stack that comprises the arch, likewise as the one or more flat springs at the bottom. The commodities is used as the starting point for measuring the length of a given set up of leaf springs. However, since the bolt is commonly not in the bodily center, it'southward always of import to measure out each side separately, starting from the bolt. In short, the eye bolt is known for the post-obit characteristics:- A vertical bolt about the eye of the springs

- Holds the top and lesser springs together

- The starting point when measuring leaf springs

- The finish tips

On most leafage springs, the cease tips are also known as the eyes because of the enclosed, curled shape. On some foliage springs, the arch simply comes to an cease with no ringlet at the tip — these are known as slipper springs. On most leaf springs, the tips are identical, whether it'southward an centre or slipper. However, some sets have both types of ends, such equally an eye at the front end tip and a slipper at the dorsum.

How to Decide Leaf Spring Size

If yous want to know how to determine foliage spring size, you lot need to remember of leaf springs every bit multidimensional components. Basically, the size of a leaf spring can only be determined when measurements at all angles are taken into business relationship. Therefore, y'all need to measure the width, height and thickness of the spring stacks, just nigh importantly, you lot need to mensurate the length of the summit spring. The needed measurements can exist broken into the following four categories:

- Leafage spring length. The length of a leafage spring is adamant past the number of inches between the tip of the front eye or slipper, and the tip of the dorsum eye or slipper. In all leaf leap sets, information technology's the long spring — the pinnacle spring — that is measured for its length, since the number of inches forth this spring accounts for the greatest amount of length in a given gear up.

- Leaf leap width. A leaf jump's width is measured by the distance from 1 edge to the other forth the top spring. On almost leaf springs, the width is betwixt 2.five inches and 3.0 inches. Whereas the length of leaf springs correlates to the measurements of a vehicle's rear-axle suspension, the width is an indicator of the shock absorption needs of a given vehicle.

- Leaf spring pinnacle. The height of a leaf bound is determined past the thickness of the springs from top to bottom, too as the space that fills the arch. Therefore, pinnacle is determined by more than just the measurements of the middle bolt. To determine the summit of your leaf springs, you lot need to place them upside down on a apartment table and measure out the vertical distance from the surface of the table to the bottom tip (upturned) of the center bolt.

- Foliage leap thickness. Once the length, width and meridian of a foliage spring are measured, the thickness of the springs should besides be taken into account. This tin be done by merely running a tape mensurate vertically down the edge of the pinnacle leap. A measurement of private bound thickness won't add to what you already know about the overall top of a leaf spring set, but it will let you know the preferred thickness of springs for the gravity assimilation of a given vehicle.

How to Measure Leaf Springs

A lot of vehicle owners are initially dislocated nearly how to measure leafage springs. The confusion stems from the mutual perception of length, which most people imagine would mean the distance between both eyes of a leafage bound set. As such, information technology'due south often assumed that foliage springs can easily be measured by turning them upside down on a surface and measuring the eye to eye distance with a ruler. However, this is an error when it comes to accurately determining the measurements in question.

For starters, leafage springs are not merely meant to be measured from 1 end to another considering this won't give an accurate measure of the jump surface. For leaf spring measurements to be accurate, the following steps must be taken according to the spring type at hand:

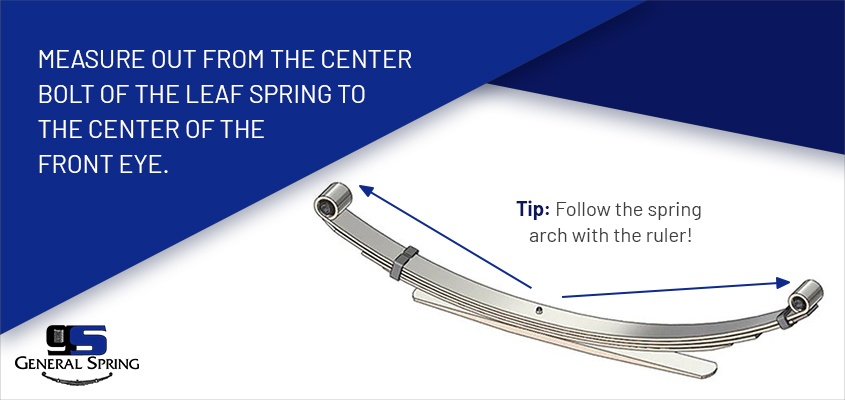

- Eye to eye. To measure out the length of a top spring with eyes at both ends, starting time your record measure out at the center bolt and extend the ruler record against the surface until it reaches the center of the front heart. While measuring the leaf spring, follow the arch with the ruler. Accept the measurement downward, and so perform the aforementioned measurement in reverse, this time measuring the distance along the bound surface from the center commodities to the heart of the back center. Combine the two measurements into i, and you'll have the length of the longest leaf jump.

In some cases, the 2 half measurements are fifty-fifty, which confirms that the bolt is situated at the center of the fix every bit a whole. With other leaf springs, however, there could be a disparity of as much as five inches between the two one-half measurements, which would indicate that the top jump extends farther in one direction. - Heart to slipper. On leaf springs with an center at one end and a slipper at the other, the fashion to gain an accurate measurement of the overall length is much the same as with an centre-to-eye top spring. Start at the center bolt, extend the tape measure along the surface of the spring to the center of the eye, then take that measurement. Echo that step in reverse, starting at the middle commodities and extending along the other half to the tip of the slipper, with the ruler following the curvation, then combine the two measurements.

It must be noted here that slippers come in several different shapes, including the following:

- Flat end, where the inverted arch turns flat and horizontal at the terminate.

- Radius end, where the inverted arch curves downwards toward the end.

- Open centre, which curls up and over like an eye, but without shutting into a full circle.

- Hook terminate, a apartment end that turns 45 degrees downward at the tip.

- Slipper to slipper. When measuring the length of a slipper-to-slipper top spring, the shape of the slipper determines whether the ruler must extend to the physical end of the tip. On regular, flat-end and radius slippers, the ruler ends from the center commodities to the concrete tip of the slipper. On open-eye and hook-end slippers, the ruler extends to the outermost portion of the finish, which would be the bespeak at which the slipper turns downward or curls upward. As with eye-to-middle leaf springs, yous combine measurements from the center bolt to both ends along the arch.

- Camel back. On Mack trucks, in that location's what's known equally the camel-dorsum foliage jump set, which consists of numerous leafs and is birthday very different from other leaf springs. The proper name is due to the shape of the pattern, which humps upwards like a camel's back. As such, they feature an upright arch rather than the inverted arch of eye and slipper foliage springs.

Since the smallest foliage is at the top, there's no need for a apartment foliage — every foliage is function of the camel. Another distinguishing characteristic is the placement of the longest foliage, which is second from the lesser and is therefore non the outermost leaf in the set. The longest leaf is sandwiched past 2 leaves of matching length. It's the length of those two second-longest leaves that yous want to measure, starting from the centre commodities and extending outward in both directions.

- Single point. Heavy-duty trailers are often equipped with single-point leaf springs, which — similar the camel back — are designed in the shape of an upright arch, as opposed to an inverted arch. However, the arch is slight on a single bespeak. Therefore, the smaller top leaves are mostly flat, while the bottom leaves form a small, shallow loma. The length to the cease tips of the lesser leaf are measured in halves, starting from the center bolt in each direction.

Determining Replacement Leaf Springs by Vehicle Make/Models

If you're wondering how to measure for replacement leafage springs, the easiest method is to take the measurements of the older leafage springs y'all intend to supercede. Of course, yous'll need to elevate the rear of your vehicle and crawl under the truck or SUV with a flashlight and measuring tape. Hither are some other specifications you lot'll want to consider:

- The type of vehicle. Even though leaf springs aren't as common in today'due south compact motorcar, they are an essential addition to the rear-side chassis of vans, trucks and SUVs. The type of leaf spring used in a given vehicle can all depend on the weight capacity of the vehicle. For example, if the rear axle has a vi,000 lb. rating, the vehicle should be equipped with two 3000-lb. capacity leaf springs. As a general rule of thumb, the heavier the vehicle, the college the load capacity.

- The brand and model. The brand of your vehicle can too decide which blazon of leaf springs would be well-nigh suitable. Whether you lot drive a Ford, Chevy, Nissan or Toyota, it's best to expect for replacement leaf springs that are tailor made for the vehicle in question. At General Spring, we have a vast inventory of leaf springs made especially for the vehicle subcategories of numerous automakers, including:

- Chevrolet / GMC

- Ford / Mercury

- Dodge / Chrysler / Plymouth

- Toyota (Tacoma, Tundra, four Runner, Land Cruiser, etc.)

- Nissan (Frontier, Xterra)

- Jeep (Wrangler, Cherokee, Comanche, Jeepster / Commando, etc.)

- The OEM part number. If you can locate the OEM role number on the leaf springs that came with your vehicle, yous'll have an easier time finding replacement leaf springs that friction match. The OEM number — also known equally the stamping number — is typically found in 1 of several places:

- The longest foliage, on the underside nigh the center or slipper.

- The end of the eye wrap, at the identify where the circle curls in.

- The foliage clips, on the bottom, top or sides of the clips that bound the leafage springs at quarter lengths.

- The bottom foliage, on the lesser side near the center bolt.

- The capacity of your springs. Another way to determine the best replacement leaf springs for your vehicle is to count the number of leaves stacked within the electric current leaf springs. Equally important here is the thickness of the springs in question, which has a huge begetting on gravity absorption. Simply put, yous'll want to find new leaf springs with the aforementioned absorption capacity as the bound sets yous're replacing because those old springs at one fourth dimension were optimal for the vehicle.

How to Check Leaf Springs

Leaf springs protect the rear of big vehicles from gravity stress caused past heavy loads and vehicle components. Without leafage springs, a truck can easily sag in back whether loaded or not, but it can sag extensively when loaded with objects of considerable weight. Moreover, trucks are actually designed with a slight hike in back to compensate for the natural sag heavy loads can cause.

Therefore, when the back of your truck fails to absorb gravity, it'southward likely due to declining leaf springs that need to be inspected and mayhap replaced. To make up one's mind this, yous need to know how to bank check leaf springs for damage, and also monitor the balance of your vehicle. Keep an middle out for:

- Corrosion. The biggest enemy to almost all forms of metallic is rust, which tin can spread over the surfaces of metal objects and ultimately eat correct through. Once rust has taken concur, it's generally hard to articulate away. Therefore, a rusted set of leaf springs should be replaced earlier the bodily leaves begin to snap, break and neglect on a given vehicle at dangerous moments.

- Cracks. The most tell-tale sign that leafage springs need to exist replaced is when cracks appear on the leaves. Oftentimes times the stop issue of rust, cracks could crusade the leafage springs to fail outright, which would go out your back-rear suspension in peril, specially if your vehicle carries a heavy load. Similarly, if parts of a leafage have chipped off, it'southward definitely time for new leaf springs.

- Leaning. If the truck seems to lean to one side, it'south an indicator that a newly installed leaf leap on ane side is ill-matched to the other or that one spring has given out. Leaf springs demand to be compatible on both sides for fifty-fifty distribution of rear-end gravity suspension. Therefore, information technology'southward important that leaf springs of the same model be used on a given vehicle. On older vehicles, it'due south generally best to supplant both leaf springs at once, even if only one of the leaf springs has shown noticeable signs of wear.

- Pause sag. Monitor the performance of the rear suspension to your vehicle. Does your truck sag in back when loaded with heavy objects? If your headlights are pointing upward and your seat feels like a rocking chair, chances are your leaf springs are declining to provide sufficient gravity assimilation. Does your vehicle sway heavily when you drive over speed bumps? This shouldn't be happening if your rear axles are equipped with optimal leaf springs.

Suspension sag is a dangerous symptom for your vehicle because it's hard on your back tires and beam. When your truck sags, information technology can also brand driving uncomfortable considering your seat is unable to offering sufficient back support. Furthermore, suspension sag causes your headlights to aim too loftier and smooth direct through the windshields of oncoming motorists.

Some vehicles have low weight capacities that can barely handle a full load of passengers. That means no affair what you're driving, it's vital to have optimized leaf springs.

Go New Leaf Springs at General Spring

Now that you know how to measure foliage spring length as information technology applies to your vehicle, the time has come to swap your one-time, worn down springs for fresh new ones. Whether you drive a car, truck, van or SUV, at General Jump, we carry leafage springs of various sizes and thicknesses. The moment your new springs are installed, your Ford, Chevy, Nissan or Toyota will have optimal gravity absorption for the nearly challenging terrain. To encounter our inventory, visit our foliage spring pages today.

How To Tell What Size Lift Leaf Springs I Have?,

Source: https://www.generalspringkc.com/blog/how-to-properly-measure-leaf-spring-size-for-your-vehicle/

Posted by: millerdurstownsee.blogspot.com

0 Response to "How To Tell What Size Lift Leaf Springs I Have?"

Post a Comment